PhD Candidate Uses 3D Printing for Resident Training Dissertation Project

Joshua Krech, a PhD candidate in Anatomy at Ohio State University, is using 3D printing to revolutionize medical training. Through his dissertation, Krech is developing a 3D-printed hip joint model for training medical residents in ultrasound-guided needle injections. Traditional methods are costly and limited, but Krech’s high-fidelity models provide a cost-effective, repeatable alternative.

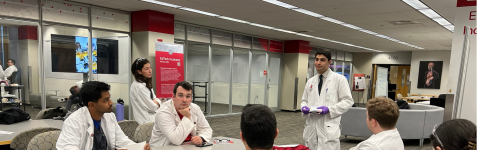

The Ohio State University Department of Anatomy PhD candidate, Joshua Krech, teaches the Intro to 3D Printing for Health Sciences Students course and has partnered with the EdTech Incubator (ETI) since its inception for his PhD dissertation project. As someone exploring practical uses for the ETI, Krech’s use of the technology hub as a student and teacher has allowed him to play a crucial role in elevating the ETI’s resources for practical, educational and research purposes.

The Exploration

In the first semester of Krech’s PhD program, College of Medicine faculty Derek Harmon, PhD asked Krech if any of the doctors he shadowed in his undergraduate years shared specific pain points related to training medical students, residents and fellows. Krech recalled how the orthopedic doctors shared that there were an abundance of joint issues and difficulties with pain management regarding opioid use in his Ohio hometown. They also shared how difficult it is to teach residents to treat these joint issues because patients of varying sizes make every joint ultrasound and needle injection different and require a lot of practice to do well.

The traditional way for residents to practice their ultrasound and needle injection skills is with donor bodies, which is an expensive and often cumbersome process for skills that require repetitive training. This became Krech’s inspiration to explore 3D printing as a different tactile simulation technique for his PhD dissertation project. He started by looking at research that has already been done and conducted a systematic review of all 3D models that are being used for tactical training with medical residents. His article, which was approved in December 2024, highlighted the lack of tactile ultrasound training provided to residents.

The Solution

Krech’s goal with his dissertation is to create a 3D-printed anthropomorphic (human-like) phantom (ultrasoundable) model for resident education and training. His prototype is a hip model for residents using an ultrasound probe to examine the joint and inject it with a needle.

Since prints that come from resin 3D printers are not ultrasoundable, Krech used a CT scan to instead 3D-print a resin mold of the hip, including the bones and joint capsule that make up the hip joint. He created the joint capsule by filling the mold with a thin layer of silicone and then inserted the femur bone inside. Then he placed the resin bone with the silicone sleeve inside the larger mold and filled the middle layer with ballistics gel to construct an anthropomorphic phantom hip joint. Residents can use an ultrasound probe on Krech’s model to help practice needle placement.

The creation of this high-fidelity hip phantom can provide a framework for Graduate Medical Education programs to implement joint training workshops using his method of creating 3D printed joint phantoms. The tactile educational simulation not only helps residents throughout their training, but also improves the patient experience when residents can get ample practice of 3D-printed models before injecting directly into a patient’s joint. This method focuses on value-based care and can provide more equitable means of training residents on musculoskeletal related procedures.

The Experience

Throughout his dissertation project, Krech primarily used the ETI’s 3D printing lab and the Ohio State College of Nursing Innovation Studio. Throughout the process, the ETI team asked Krech for recommendations to improve the process, which resulted in additional tools to help clean the 3D printers, updated 3D resin printer models and the addition of a Bambu filament printer. You can learn more about this updated technology on our 3D Printing Lab page.

When asked about his experience with the ETI equipment and the team that runs it, Krech said, “Amazing. They have been very, very helpful with my project and the 3D printing course that I run... Having computers available [in the ETI’s computer lab] for students to use has been huge.”

Krech is currently applying for assistant professorships and hopes to develop the same resources at another university. After helping Harmon, ETI Coordinator Mo Duncan and others as the ETI continues to grow, he has transferable knowledge of startup costs for a technology hub, supplies needed and how to collaborate across departments for cooperative, forward-thinking medical training.